Saint Stephen’s welcomes 3D printer

The Tech Lab houses the new device. Come see it for yourself!

January 6, 2015

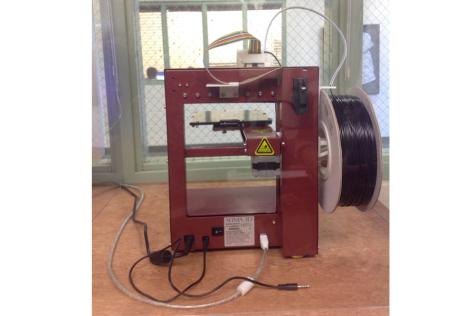

A green light flashes. A mechanical arm hastens back and forth, releasing a small plastic substance. From a quick glance, it’s impossible to know what this mysterious machine is creating, however, come back a few hours later, and a robot, or even a small functioning car will be on the platform. That’s when you will know this device is a 3D printer. Saint Stephen’s has recently embraced this new technological advance which will give students interested in engineering and technology a unique hands-on experience in the field.

According to Mrs. Addison (tech director), a 3D printer not only incorporates height and width (features found in a 2D printer), but also adds the dimension of depth. There are two main components of this printer, the design or blueprint, and the actual printer device. The piece responsible for physically making the product is composed of a spool of plastic that heats up, and a heated platform. The function of the heated platform is to prevent the object being created from warping or cracking as it cools. The device connects to the computer, which lays out the 3D design. 3D software is used to create the design or model used. The spool of plastic then feeds into a small nozzle. It reads the design, and moves back and forth on the heated platform as it builds up the object.

3D printing has been used by manufacturers for many years, but it is just now becoming more commonly known. The use for 3D printers is diverse, and continues to grow as more technological advances are made. Currently 3D printers are breaking down medical barriers as doctors and engineers are working to create tissue, organs and blood vessels. According to 3Dprinting.com, the future of 3D bioprinting looks good, as it will possibly eliminate the need for organ donors, give doctors on-demand human tissue and create prosthetic limbs, which may cut down the price by 90%. Outside of the medical world, current materials being used to 3D print are plastics (the material used at Saint Stephen’s), glass, metal, polymers, wax, edible foods and sand and glue mixes.

One controversial issue regarding 3D printing is the fact that anyone can buy a 3D printer, and what they choose to create cannot be monitored. 3D printers are fairly reasonably priced and can be purchased for as little as five hundred dollars. The 3D printer at Saint Stephen’s costs around 1,250 dollars. The ease at which one can purchase a 3D printer is alarming considering that these machines can be used to create guns. In fact, the first 3D printed gun has already been created. According to forbes.com, this gun was printed overnight, and 15 out of the 16 parts were made of plastic. The blueprint was shared online and downloaded 100,000 times to make copy guns before the government took it down. This just goes to show, with all beneficial advancements comes some type of controversy.

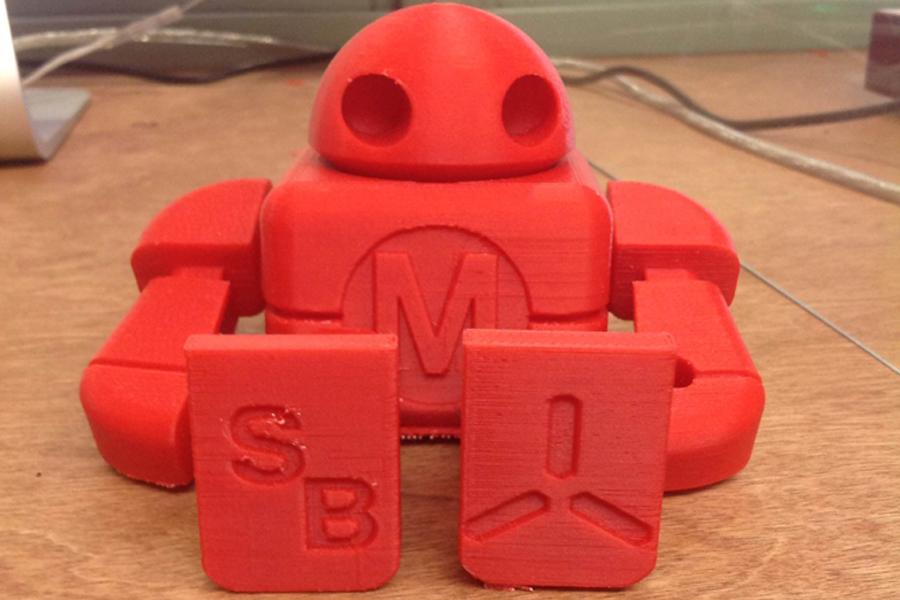

As of now, the 3D printer at Saint Stephen’s is being used as a learning tool. Students and staff have progressed from creating single-piece objects, to pieces that fit together. For example, the printer recently created an object with working hinges (see red object above).

For any students interested in 3D printing your future looks bright, as Mrs. Addison says the technology department hopes to “Get into some kind of engineering and design and have students creating models and experimenting.”