Senior produces, distributes over 200 face shields in fight against COVID

Senior Michael Mills has produced over 200 3D printed face shields to help fight the pandemic.

“At first, the change was exciting because it was novel,” senior Michael Mills said about living in quarantine as the result of the Coronavirus pandemic. But he added that after a couple of days, “it all changed— I came close to tears multiple times. Then, I decided to act.”

Mills’ face shields fully cover the eyes, nose and mouth of medical professionals to help thwart the spread of COVID-19.

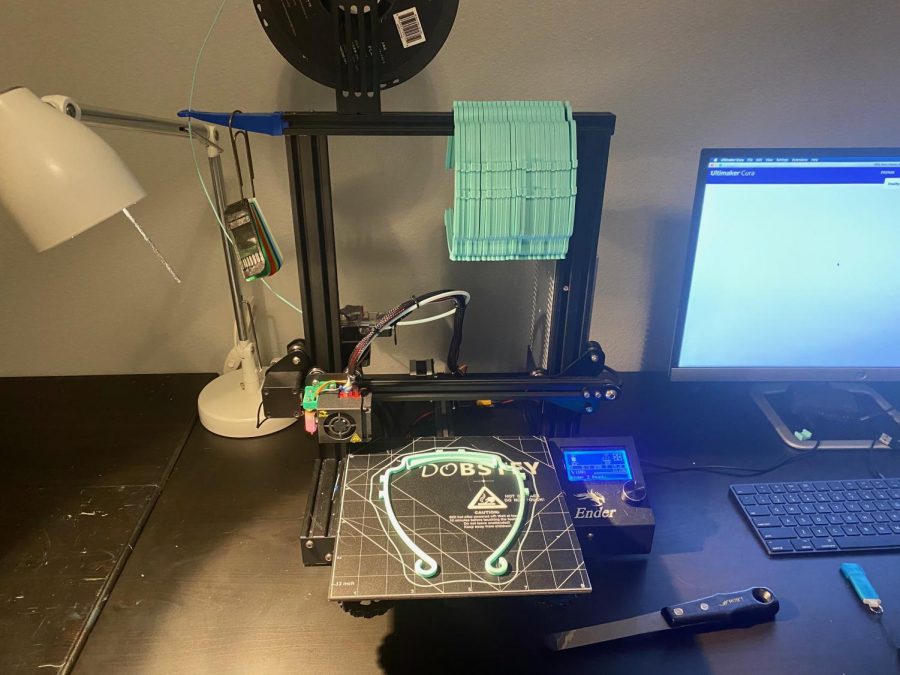

Instead of filling his time with video games and Netflix during those first days of quarantine, Mills focused his efforts on designing and producing 3D-printed “face shields” (transparent medical-style masks) with his home 3D printer.

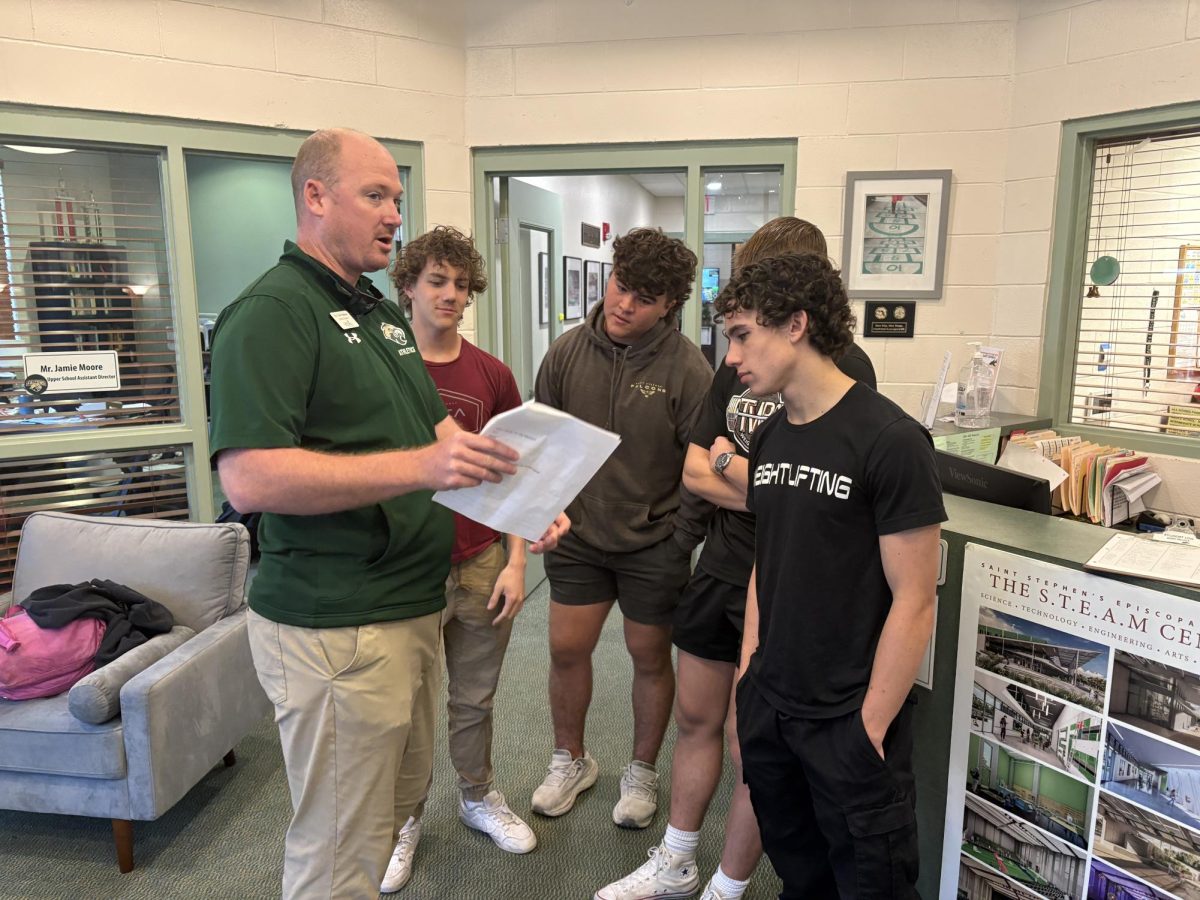

Mills, a senior, has been embedded in the Saint Stephen’s technology department for years, participating as a tech intern, taking computer science classes, and enrolling in engineering. One of his areas of focus was 3D printing, a skill that is now paying dividends.

Once he got the 3D-printed masks rolling, he began donating them to local medical professionals in the area. Mills said felt “a sense of urgency to help the community.”

Mills’ actions have caught the attention of some local media outlets, such as the Sarasota Herald-Tribune, SNN, and the Bradenton Herald, who have all interviewed Mills.

Following his early success, healthcare organizations such as the American Lung Association, a hospital in Alabama, an anesthesiology group in Sarasota, and Sarasota Memorial Hospital have all reached out to Mills on Facebook inquiring about his product.

To date, Mills has produced and distributed about 200 face shields, working “pretty much all day,” to meet the rise in demand. He averages about thirty shields every 24 hours.

When she caught wind of the news, Saint Stephen’s Head of School Dr. Jan Pullen reached out to Michael, commending him for his work. She also sent him shipments of Ziploc bags to help fuel the distribution process.

Various teachers and staff at the school have also reached out to him, asking him for shields to distribute to their friends and family who work in the medical field.

The 3D printer is capable of rolling out 30 masks a day.

“I am proud to be getting recognition from my school and local media sources. It feels good. But more importantly, I feel a strong sense of fulfillment from knowing I’m making a positive difference in communities that need help.”

Mills’ work is just another example of how our country is pulling together to fight this virus together.

Mills added that the experience has made him think about making community service a part of his life: “The work has inspired me too… I’ve been thinking about my future, and I want to settle down with a normal 9-5 job so I will have the time to do volunteer work on the side.”

If you or anyone you know in the community is need of a face shield, contact the [email protected].